HTD belts, or High Torque Drive belts, are widely used in mechanical systems. They ensure smooth power transmission. The thickness of an HTD belt is a critical factor in its performance. Understanding how thick an HTD belt should be is essential for efficient operation.

What Is an HTD Belt?

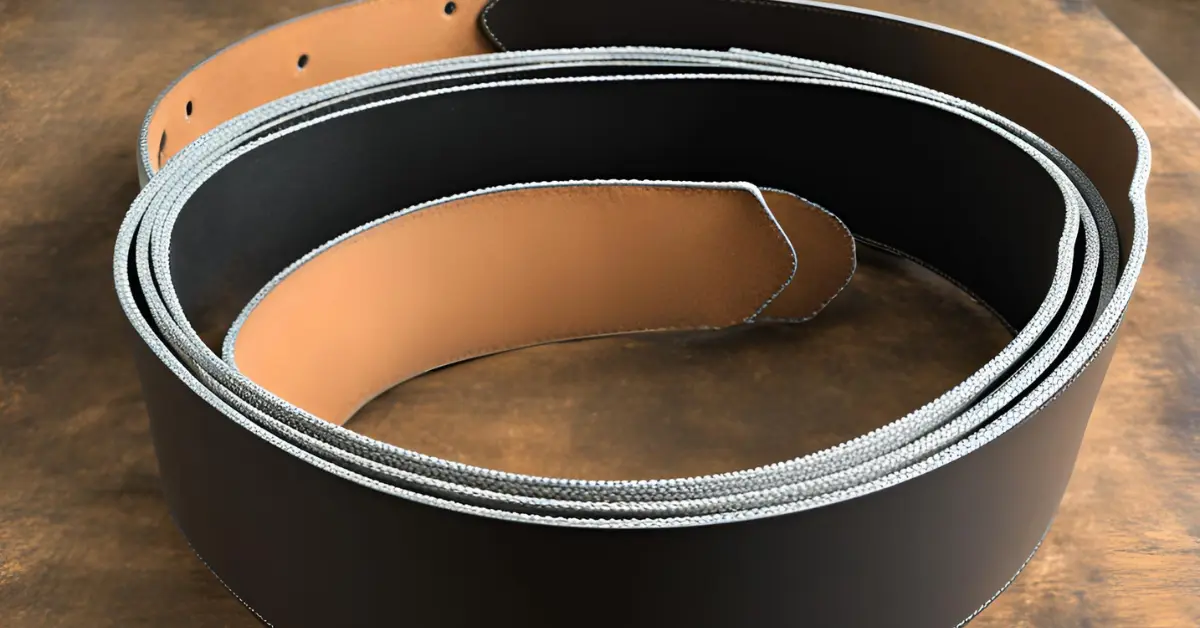

HTD belts are toothed belts. They are designed for high-torque applications. These belts provide better grip compared to flat belts. The design minimizes slippage, ensuring consistent power transfer.

Importance of Thickness in HTD Belts

The thickness of an HTD belt impacts its strength and flexibility. A belt that is too thin may wear out quickly. A belt that is too thick may not fit correctly in the pulley. Correct thickness ensures optimal performance and longevity.

Standard Thickness of HTD Belts

HTD belts come in various sizes. Each size has a specific thickness range. Here are common HTD belt profiles and their standard thickness:

3M HTD Belts

- Pitch: 3 mm

- Standard Thickness: 2.4 mm

5M HTD Belts

- Pitch: 5 mm

- Standard Thickness: 3.8 mm

8M HTD Belts

- Pitch: 8 mm

- Standard Thickness: 6 mm

14M HTD Belts

- Pitch: 14 mm

- Standard Thickness: 10 mm

The pitch refers to the distance between teeth. As the pitch increases, the belt’s thickness also increases.

Factors That Affect HTD Belt Thickness

Several factors influence how thick an HTD belt should be. These include:

Load Capacity

Thicker belts can handle higher loads. For heavy machinery, choose a thicker HTD belt.

Pulley Size

Pulley size determines the belt’s compatibility. A thick belt may not fit smaller pulleys. Always match the belt thickness to the pulley size.

Speed Requirements

High-speed systems often need thinner belts. Thin belts reduce friction and heat buildup.

Material of the Belt

HTD belts are made from rubber, polyurethane, or other materials. Material choice affects the belt’s thickness and durability.

How to Choose the Right Thickness for an HTD Belt

Selecting the correct thickness ensures efficiency. Follow these steps:

- Check the Manufacturer’s Specifications Always refer to the manufacturer’s guide. It provides the recommended thickness for your application.

- Consider the Application Understand the system’s requirements. For heavy loads, opt for thicker belts. For lightweight systems, thinner belts are better.

- Measure the Pulley Groove Measure the pulley’s groove depth. This helps determine the belt’s maximum thickness.

- Test for Compatibility Install the belt and check for proper fit. Ensure it runs smoothly without slipping or excessive tension.

Advantages of Choosing the Right HTD Belt Thickness

Correct thickness offers several benefits:

- Improved Performance: Ensures efficient power transmission.

- Longer Lifespan: Reduces wear and tear.

- Cost Savings: Minimizes the need for frequent replacements.

- Reduced Noise: Ensures quiet operation.

Common Mistakes When Selecting HTD Belt Thickness

Avoid these mistakes to ensure optimal performance:

Ignoring Manufacturer Guidelines

Using a belt that doesn’t meet specifications can lead to failure.

Overlooking Pulley Compatibility

A belt that is too thick or thin may not fit properly.

Neglecting Load and Speed Requirements

Mismatched thickness can cause premature wear or inefficiency.

Maintenance Tips for HTD Belts

Proper maintenance ensures the belt remains in good condition. Follow these tips:

- Inspect Regularly Check for cracks, wear, or damage.

- Clean the Belt Remove debris and dirt. Use a soft cloth to avoid damage.

- Check Tension Ensure the belt has proper tension. Over-tightening can damage the belt.

- Replace Worn Belts Replace the belt if it shows signs of wear. Using a damaged belt can harm the system.

Similar Keywords to Use

- HTD belt dimensions

- HTD belt specifications

- HTD belt thickness guide

- Choosing HTD belt size

- High torque drive belt thickness

Using these related keywords helps improve SEO and ensures comprehensive coverage of the topic.

Conclusion

Understanding how thick an HTD belt should be is essential for system efficiency. The thickness impacts performance, durability, and compatibility. Always follow manufacturer guidelines and consider the application’s requirements. Proper selection and maintenance ensure the belt performs optimally and lasts longer. For the best results, match the belt thickness to your system’s needs.